18 May,2017 UTC+8 Views:

In recent years, with the continuous development of industrial production. Grinding equipment from the ball mill to the development of vertical mill equipment, it has also undergone a historic reform.

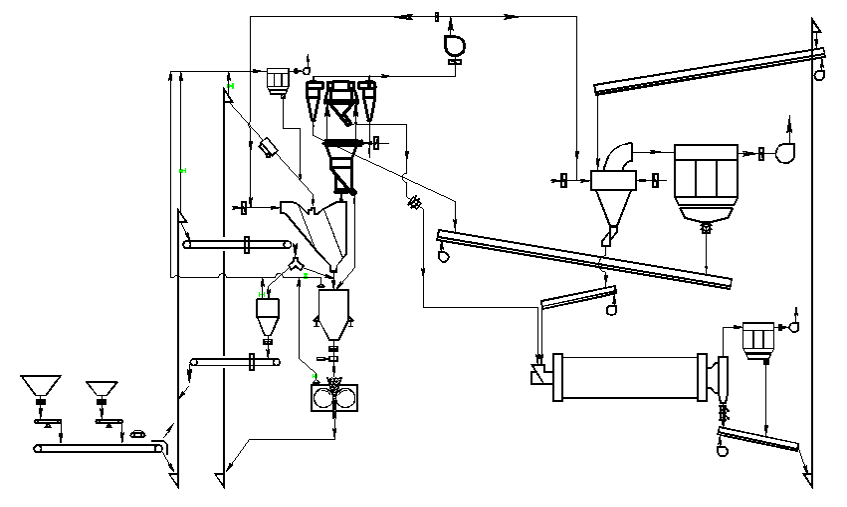

The traditional ball mill system is more cumbersome compared with the vertical mill. The whole system construction body consists of multi-layer frame building, the equipment is distributed among the layers of the equipment, the equipment connecting the pipeline through the layers of the frame. At the same time dust, covers an area of up to noise. Not suitable for moisture content of raw materials, quality is difficult to control.

Replacement of the vertical mill grinding equipment in the process system has made a huge change. Set up grinding, transportation, powder, drying in one of the vertical mill equipment greatly saves the area, closed production space system also reduces the noise, while reducing the dust pollution. For a variety of materials have different parameters set, the material is more easy to adjust.

System operating rate, ball mill system shutdown rate is high, online stacking consumes a long time, the system operation rate is low. Vertical mill is very low downtime, on-line welding time, the system operating rate is high.

The times are constantly evolving, and the progress of the production of the mill equipment is just beginning. Chaeng become "ground mill of the successor and carry forward", focused on the production of vertical mill, making the production of industrial waste grinding to achieve better results.