【Product description】: Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials

【Product capacity】: 30-720 t/h

【Power】: 25-30 KWh/t

【Specific surface area】: 330-380m²/Kg

【Motor Power】:25~30 KWh/t

1. Technique and technology is mature and stable

2. Reducing the power consumption of cement clinker preparation effectively

3. Stable, high-efficiency and environmental protection

4. With a strong casting capability and short delivery period

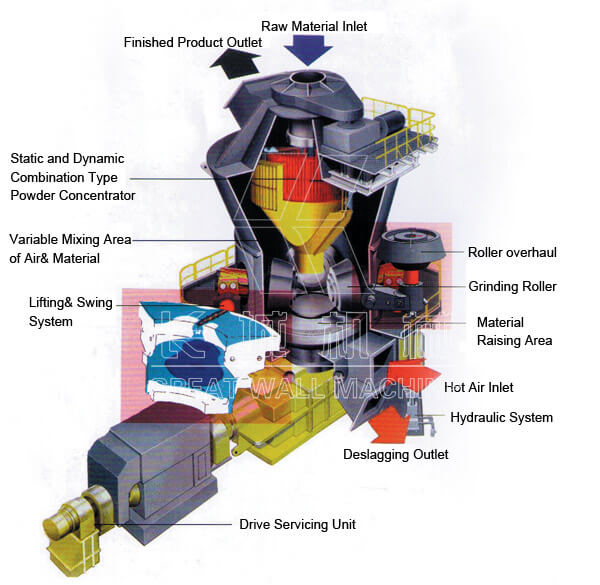

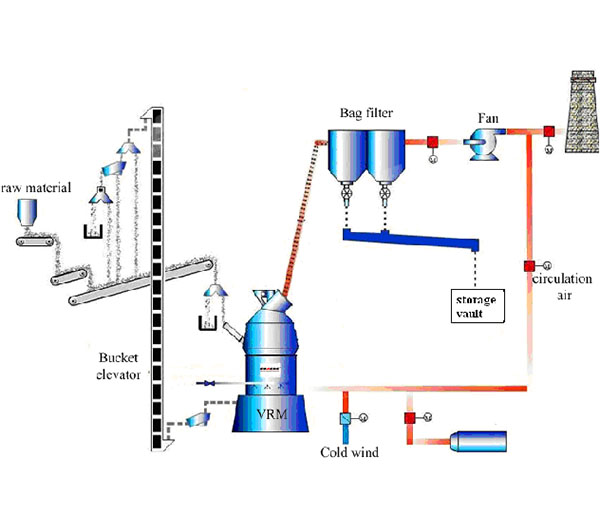

The material through the feed tube fell into the center of grinding plate, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of rollers. The materials continuous moving to the outer edge of the grinding plate, off the grinding plate materials rising with the hot air which enter from wind ring into the vertical roller mill, through the vertical grinding mill shell into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates. Separator controls the finished product output size, greater than the specified size are separated and fall back to the plate, while meet the fineness demands are brought through the separator into the finished product warehouse.

| Specifications | Grinding Table Diameter (mm) | Output (t/h) | Motor (kW) | Output (t/Y) |

|---|---|---|---|---|

| GRMK26 | 2600 | 40~45 | 1250 | 250,000 |

| GRMK30 | 3000 | 50~55 | 1400 | 300,000 |

| GRMK33 | 3300 | 60~65 | 1600 | 400,000 |

| GRMK36 | 3600 | 75~85 | 2000 | 500,000 |

| GRMK38 | 3800 | 85~95 | 2240 | 550,000 |

| GRMK40 | 4000 | 100~110 | 2500 | 600,000 |

| GRMK43 | 4300 | 125~135 | 3150 | 800,000 |

| GRMK46 | 4600 | 140~160 | 3550 | 900,000 |

| GRMK50 | 5000 | 160~180 | 4000 | 1,000,000 |

| GRMK53 | 5300 | 180~200 | 4500 | 1,200,000 |

| GRMK56 | 5600 | 210~220 | 5300 | 1,300,000 |

| GRMK60 | 6000 | 250~270 | 6300 | 1,500,000 |

| GRMK65 | 6500 | 300~330 | 7300 | 1,800,000 |

| GRMK70 | 7000 | 350~380 | 8500 | 2,200,000 |

300,000 t/a Vertical Cement Mill in Pakistan

The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollution. It is widely used for clinker grinding production in cement plant. CHAENG can provide various types of vertical cement mills with productivity of 50-250t/h. The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill.

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China